how we craft

THE ORIGINAL TASTE OF BELGIUM FROM BEAN TO BAR

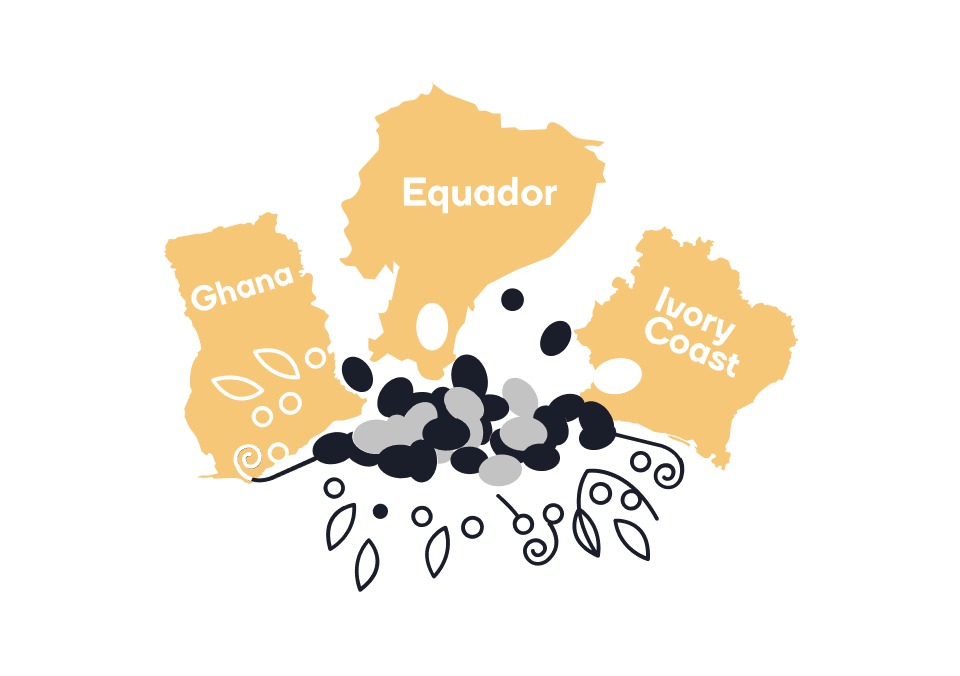

1. SUSTAINABLE COCOA FARMING

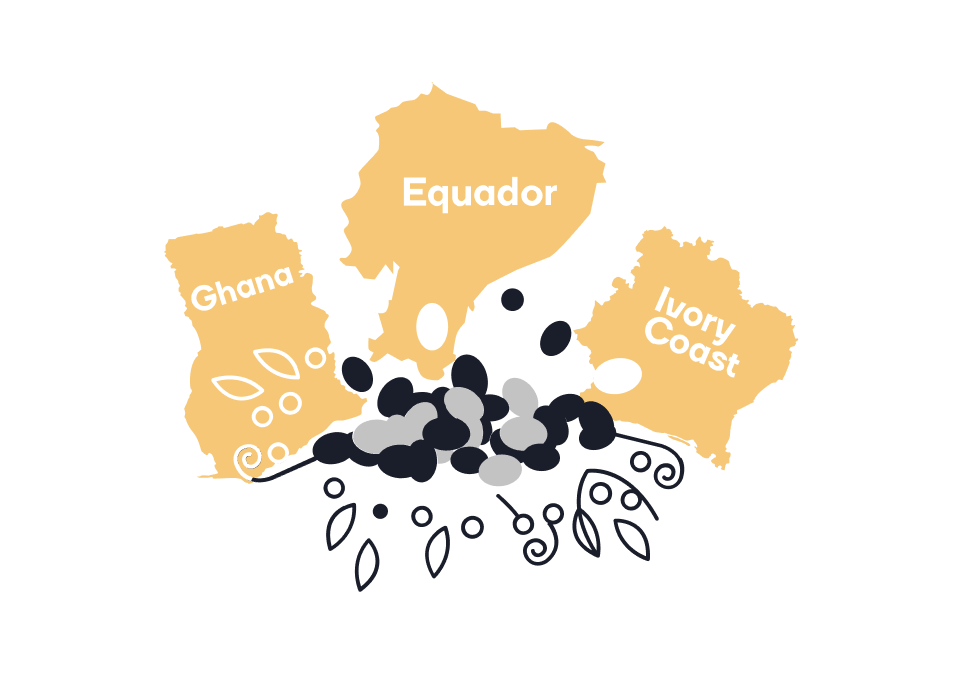

We partner directly with farmer cooperatives in Ivory Coast, Ghana and Ecuador in the Cocoa Horizons programme to grow sustainable and traceable cocoa. Through training, social and environmental projects, this programme pursues its 3 fundamental goals: helping cocoa farmers prosper in the long run, empowering local communities, caring for the environment and stopping deforestation.

2. FERMENTING COCOA BETWEEN BANANA LEAVES

After the harvest, good fermentation is essential for the typical chocolate taste precursors inside the bean to develop. Traditionally, farmers in West Africa ferment the cocoa beans in the field between banana leaves.

3. SUN-DRYING TO REDUCE MOISTURE CONTENT BELOW 8%

After fermenting, the cocoa beans are spread on mats to sun-dry and turned regularly. Drying stops the fermentation process and makes the moisture inside the bean evaporate.

4. SELECTED FOR PREMIUM QUALITY

We only select bigger, best-grade cocoa beans from the main crop. Their size and quality will yield a better and more intense cocoa taste. All beans undergo pre-cleaning and several quality checks before selection and shipping. Later in the process, beans of about the same size will be crucial for even roasting results.

5. ONLY JUTE-BAGGED BEANS

For our Finest Belgian Chocolates, we only buy jute-bagged cocoa beans. Jute is a natural material, allowing the beans to ‘breathe’ and regulating their moisture content. They’re stacked in containers for shipping to the Antwerp port, where they undergo final quality checks.

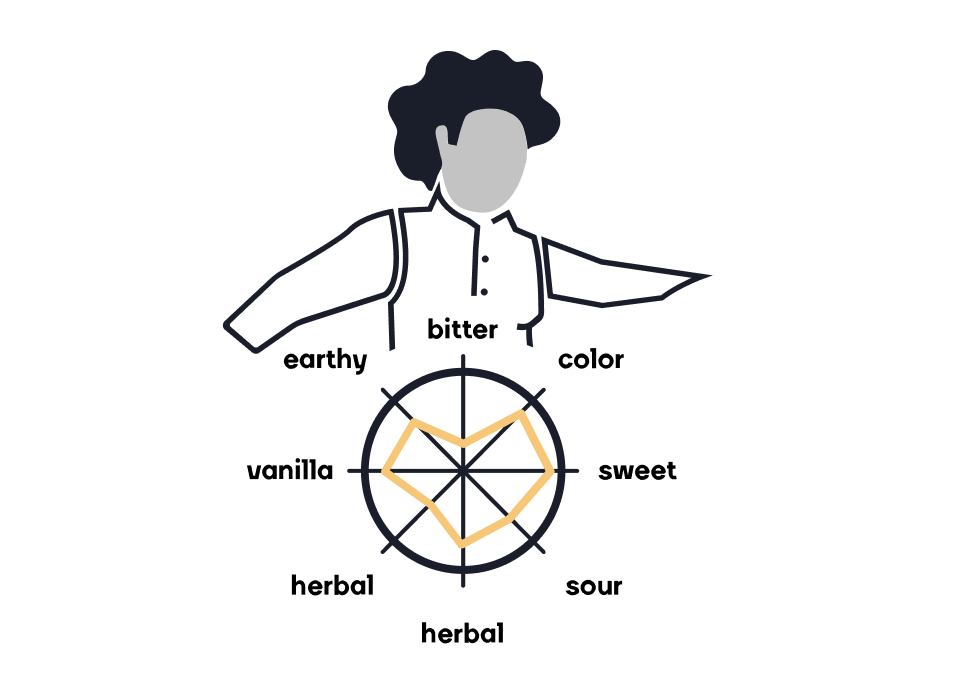

6. COCOA FLAVOUR ANALYSIS

From each bag of beans, a sample is taken to do quality checks and define the taste profile of the cocoa lot. Every taste profile is stored in our bean library. Our master blenders then use these profiles to balance out the perfect blend.

7. COMPOSING THE CALLEBAUT BEAN BLEND

As cocoa is a natural crop, variations in the taste of the beans come naturally. They’re related to the soil, the seasons climate, etc. Our master blenders continuously fine-tune the blend of beans from the Ivory Coast (typical chocolaty cocoa body), Ghana (fruitiness) and Ecuador (bitterness) to recreate the iconic Callebaut taste.

8. WHOLE BEAN ROASTING

To do justice to the work of the cocoa farmers, we roast the whole beans, protected in their shells in a unique, continuous flow. Our way of roasting exposes the beans to moderate heat for a limited time, to awaken their full taste and aromas: both the powerful cocoa flavours inside each bean and the delicate flavours. We believe it’s the best way to get the best out of every bean.

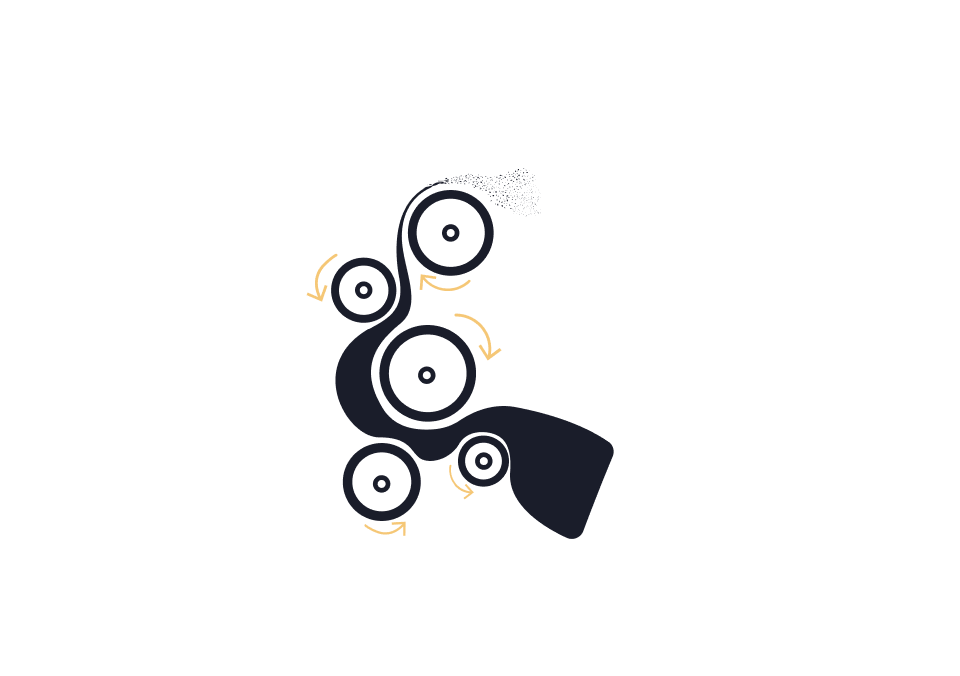

9. REFINING COCOA LIQUOR

After roasting, we break the beans. Through winnowing, we meticulously separate the shells from the cocoa nibs. The nibs are then ground in 3 different grinding steps to ultimately become our fine cocoa liquor: the key ingredient for our dark and milk chocolates.

10. MIXING INGREDIENTS

Our cocoa liquor is mixed with high-quality ingredients like beet sugar and – depending on the recipe – different kinds of milk and natural vanilla, to create the chocolate dough.

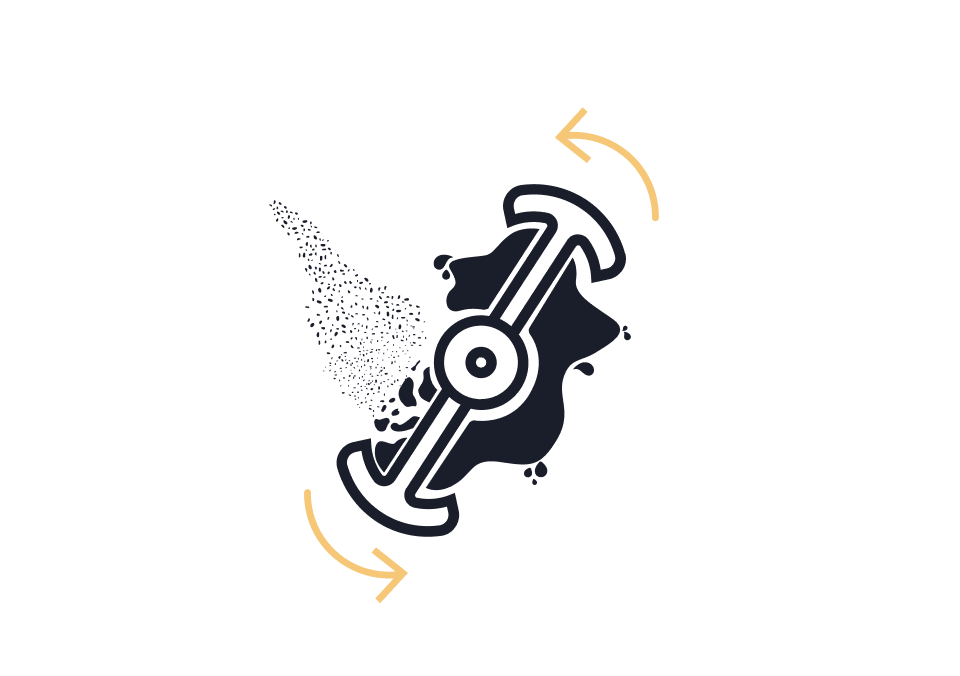

11. 5-ROLL REFINING

We refine our chocolate dough between 5 sequential rolls to reduce the particle size of all ingredients. The particles will become smaller than the distance between 2 taste buds - which will create the typical silky smooth texture and delightful mouthfeel.

12. CONCHING THE CHOCOLATE

Conching will develop the final taste of our chocolate. At the start of the conching process, the chocolate is still too acidic in taste. In a 2-step conching process, our master conchers will preserve the right amount of fruity and sour notes in our chocolate recipes while getting rid of too acidic volatile flavours. On top, conching will create the incredibly smooth, velvety mouthfeel chefs appreciate in our chocolates.

13. MAKING SIGNATURE BLOCKS & CALLETS™

Finally, the chocolate is tempered and moulded into our signature 5 kg-blocks or Callets™: little drop-shaped chocolate pieces that ensure great usability, an invention by Callebaut®.

TAKE THE TOUR OF OUR WIEZE CHOCOLATE FACTORY

-

PART 1 – THE BEANS THAT MAKE THE CUT

Where do the cocoa beans for our chocolate come from? And what makes them special? Kirsten Tibballs takes you on our bean-to-bar tour -

PART 2 - QUALITY OF THE COCOA BEANS

We only use the best-grade cocoa beans. But what does this mean? And how do we select them? Kirsten Tibballs discovers it here. -

PART 3 – COMPOSING OUR COCOA BEAN BLEND

How does a blend of 3 different types of bean define the original taste of our chocolate? Does that blend ever change? Kirsten Tibballs looks for the answers. -

PART 4 – WHOLE BEAN ROASTING FOR THE WHOLE TASTE

What is whole bean roasting? What does it do for our chocolate taste? And why do we believe already for more than 100 years that it is the best way to roast the cocoa beans? -

PART 5 – THE ORIGINAL COCOA LIQUOR: THE HEART & SOUL OF OUR CHOCOLATE

How do we get from roasted beans to cocoa liquor? And what exactly makes our cocoa liquor so fine? Kirsten Tibballs finds all the answers with our cocoa specialists. -

PART 6 – QUALITY CHECKING THE TASTE OF THE COCOA LIQUOR

How do we know for sure the cocoa liquor will exactly yield the taste we're after for our chocolate? Kirsten Tibballs checks it out for you. -

PART 7 – WHAT INGREDIENTS DO WE SELECT FOR OUR CHOCOLATE?

Cocoa liquor is the key ingredient. But which other ingredients make the selection? Sugar, vanilla, milk and sunflower lecithin: what do they do for taste? -

PART 8 – FINE, FINER, FINEST: 5-ROLL-REFINING

Where does the fineness of our chocolate come from that gives it that velvety smooth mouthfeel? Kirsten Tibballs finds it out for you. -

PART 9 – CONCHING THE ORIGINAL FINEST BELGIAN CHOCOLATE TASTE

What is conching? How do we conch. And how does it help to create our chocolate taste. Kirsten Tibballs find out from our Master Concher. -

PART 10 – TESTING AND FINETUNING THE FLUIDTY OF OUR CHOCOLATE

What is fluidity? How does it determine what you can do with our chocolate. And how do we guarantee consistent fluidity and never-failing workability. Kirsten Tibballs explores how that works. -

PART 11 – OUR CHOCOLATE TAKING ITS FINAL SHAPE IN CALLETS™ & BLOCKS

Why blocks? Why Callets™? Is there any difference in the chocolate we use for both? Kirsten Tibballs looks for the answers.